The world of protein expression has changed a lot over the past decade. Cell-free protein synthesis (CFPS) is now a strong alternative to traditional cell-based methods. While cell-based protein expression has been the gold standard for years, growing evidence shows that cell-free systems offer clear advantages that make them better for many uses. This shift is more than just new technology. It's a new way of thinking about how we make proteins, moving from complex cellular environments to carefully controlled lab systems.

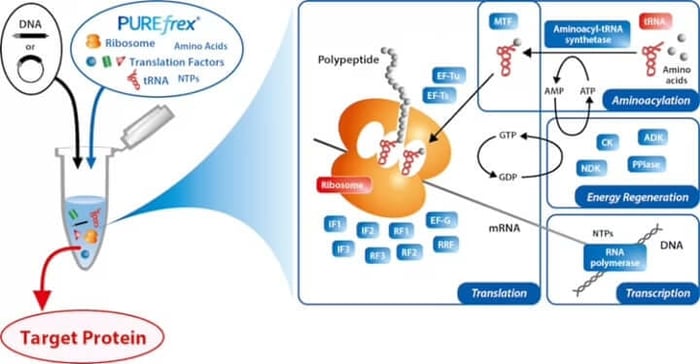

Cell-free protein expression, also called in vitro protein synthesis, uses the machinery that cells normally use to make proteins, but takes it out of the cell. Instead of using living cells as protein factories, CFPS systems use purified cellular parts or cell extracts to make target proteins directly in test tubes or bioreactors.

Speed and Efficiency: Getting Results Faster

One of the biggest advantages of cell-free systems is how fast they work. A cell-free reaction, including extract preparation, usually takes 1–2 days, whereas in vivo protein expression may take 1–2 weeks. This huge reduction in time comes from cutting out several slow steps that are built into cell-based systems.

Traditional cell-based expression requires gene cloning, putting genes into host cells, picking the right clones, growing cell cultures, and long purification processes. Each step can create bottlenecks and needs careful fine-tuning. Cell-free systems skip these problems by directly adding DNA or mRNA templates to the reaction mix, so protein synthesis starts right away.

The benefits go beyond just speed. Cell-free protein expression offers a convenient method for generating small amounts of protein for a variety of applications (e.g., protein:protein interactions, protein: nucleic acid interactions, structural analysis, functional assays and toxicity screening). This quick turnaround makes cell-free systems especially valuable for high-throughput screening and research where you need fast results.

Making Toxic Proteins Without Problems

Maybe the most important advantage is that cell-free systems can make toxic proteins. Some desired proteins and labeled proteins are toxic to cells when synthesized. Since live cells are not being used, the toxicity of the product protein is not a significant concern. This changes what proteins we can successfully produce.

Traditional cell-based systems have serious limits when trying to express proteins that harm the host. Toxic proteins can mess up cell metabolism, damage membranes, or interfere with essential cell processes. This leads to poor cell health and low protein yields. Cell-free systems completely avoid these problems because there are no living cells to be damaged.

CFPS does not involve live artificial transgenic cells, avoiding the risk of cell replication and transmission, so there is no biosafety problem. This safety advantage goes beyond toxicity to include broader safety concerns, making cell-free systems particularly attractive for making potentially dangerous proteins.

Better Control and Fine-Tuning

The open nature of cell-free systems gives you great control over the protein-making environment. The lack of cell wall allows direct manipulation of the chemical environment. Samples are easily taken, concentrations optimized, and the reaction can be monitored. In contrast, once DNA is inserted into live cells, the reaction cannot be accessed until it is over and the cells are lysed.

This access lets you monitor and adjust synthesis conditions in real time, which is impossible with cell-based systems. Researchers can change buffer compositions, adjust helper molecule concentrations, add specific folding aids, or add non-natural amino acids during the reaction. Being able to fine-tune conditions as you go is a big advantage for improving protein production and studying how proteins work.

Advanced Uses: Non-Natural Amino Acids and Protein Engineering

Cell-free systems are great at putting non-standard amino acids into proteins, opening new possibilities for protein engineering and biotech applications. A major application of CFPS is incorporation of unnatural amino acids into protein structures. The open reaction environment makes it easy to add modified tRNAs and unnatural amino acids needed for these applications.

This approach lends itself to specific protein labeling with fluorescence, biotin, radioactivity or heavy atoms, via modified charged tRNA's or amino acids. Such labeling methods are essential for structural biology studies, protein interaction analyses, and single-molecule research.

Membrane Protein Benefits

Membrane proteins are one of the hardest types of proteins to express using traditional systems. Cell-free expression systems offer unique advantages for membrane protein production by allowing proteins to be inserted into artificial membrane systems as they're being made.

The addition of membrane vesicles (liposomes) enables the production of membrane proteins, including those in large-molecular-weight complexes, such as the SecYEG translocon or ATP synthase. This ability is particularly valuable because membrane proteins often fold wrong or clump together when expressed in traditional cellular systems, leading to inactive or insoluble products.

The PUREFrex® Advantage: Reconstructed Systems

Among cell-free systems, reconstructed platforms like PUREFrex represent the best in precision and control. PUREfrex represents a breakthrough in cell-free protein synthesis technology, offering a precisely engineered in vitro coupled transcription/translation system. Unlike traditional S30 translation extracts, PUREfrex utilizes a completely reconstituted system derived from E. coli translation machinery.

The key innovation in PUREFrex systems is their use of individually purified components rather than crude cell extracts. The PUREfrex system employs advanced purification protocols to achieve exceptional component purity. This rigorous purification process effectively eliminates contaminating nucleases and proteases. This level of purity leads to more consistent results, less background contamination, and better reproducibility.

Furthermore, PUREfrex 2.0 and 2.1 variants demonstrate significantly reduced RNase and β-galactosidase contamination levels. Additionally, lipopolysaccharide (LPS) concentrations have been reduced to approximately 0.1 Endotoxin Units (EU) per microliter of reaction mixture. These improvements are crucial for applications requiring high purity, such as therapeutic protein production or sensitive biological tests.

PUREFrex: Cell-Free Protein Synthesis System

Simpler Workflow and Less Complexity

Cell-free systems make the protein expression workflow much simpler. In contrast to classical in vivo protein expression, cell-free systems do not need time-consuming cloning steps, and the open nature provides easy manipulation of reaction conditions as well as high-throughput potential.

Cutting out complex biological processes like cell growth, maintenance, and optimization reduces the number of variables that can affect protein production. This simplification is particularly helpful for researchers who need to focus on protein function rather than expression optimization, and for applications requiring standardized, reproducible protocols.

Cost and Practical Benefits

While the initial cost per reaction may be higher for commercial cell-free systems, the total cost of protein production often favors cell-free approaches when you consider the reduced time investment, simpler workflows, and higher success rates for difficult proteins. Cell free protein expression systems offers several advantages over the traditional process, including the ability to produce a broad range of target molecules by altering components suited for their production, higher yield, shorter development times and low cost of production.

The cost advantages become particularly clear when you consider the cost of failed expression attempts, the time value of researchers, and the ability to process multiple samples at once. The high-throughput capability of cell-free systems enables screening approaches that would be too expensive and time-consuming with cell-based methods.

Storage and Stability Benefits

Cell-free systems offer better storage and deployment characteristics compared to living cell systems. Through freeze-drying technology, the CFPS system can be stored stably for a long time. This stability advantage makes cell-free systems particularly valuable for point-of-care applications, field research, and situations where maintaining living cell cultures is impractical.

The ability to store reaction components as stable, dried preparations eliminates the need for continuous cell culture maintenance, reducing both costs and the risk of contamination. This characteristic has made cell-free systems increasingly attractive for distributed manufacturing and emergency response applications.

Future Possibilities and Applications

The advantages of cell-free protein expression are driving innovation across multiple fields. Cell-free gene expression (CFE) systems empower synthetic biologists to build biological molecules and processes outside of living intact cells. This capability is opening new possibilities in synthetic biology, therapeutic protein production, and biotech applications.

Current research focuses on expanding what cell-free systems can do, including developing systems from more complex cells for proteins requiring complex modifications, combining cell-free systems with other biotechnologies, and scaling up cell-free production for industrial applications.

Conclusion

Cell-free protein expression systems represent a major shift in biotechnology. They offer compelling advantages over traditional cell-based methods. The combination of speed, toxicity tolerance, better control, simpler workflows, and unique capabilities for protein engineering makes cell-free systems better choices for many applications.

As the technology continues to improve, with systems like PUREFrex leading the way in precision and reliability, we can expect cell-free protein expression to become increasingly important to biotech research and development. The question is no longer whether cell-free systems can compete with cell-based methods, but rather how quickly researchers and biotech companies will adopt these better alternatives.

The future of protein expression lies not in the complex cellular factories that have served us well, but in the precisely controlled, efficient, and versatile cell-free systems that promise to speed up scientific discovery and biotech innovation. For researchers seeking reliable, rapid, and flexible protein expression solutions, cell-free systems like PUREFrex represent not just an alternative to traditional methods, but a significant step forward that addresses the basic limitations of cell-based approaches.